NON DESTRUCTIVE TESTING

Non-Destructive Testing (NDT) refers to a group of techniques used to evaluate the properties, integrity, and quality of materials, components, or structures without causing damage. NDT is crucial in a wide range of industries for ensuring the safety, reliability, and longevity of assets, while also helping to detect potential defects or weaknesses in materials without altering their form or function.

24/7 SERVICE PROVIDERS

ADVANCED NDT CONSULTANCY SERVICES

Our Advanced NDT Consultancy Services deliver innovative solutions to enhance asset reliability, ensure safety, and optimize maintenance across industries. We specialize in state-of-the-art techniques including Phased Array Ultrasonic Testing (PAUT), Guided Wave Testing (GWT), Time-of-Flight Diffraction (TOFD), Eddy Current Array (ECA), and Digital Radiographic Testing (DRT) for precise and efficient defect detection. We provide tailored strategies for complex applications, predictive maintenance programs, and ensure full regulatory compliance with global standards. Our expert consultants also offer training and certification to equip your team with the latest NDT technologies.

Partner with us to improve safety, efficiency, and asset longevity while meeting the highest industry standards.

ADVANCED NDT SERVICES

ADVANCED NDT METHODS

Unlock precision with our Advanced NDT Services, featuring PAUT, Eddy Current Array, Digital RT, TOFD, and GWT. We provide tailored solutions for reliable asset integrity, predictive maintenance, and regulatory compliance. Empower your team with expert training and cutting-edge technology to ensure safety and optimize performance.

ADVANCED ULTASONIC TESTING

Our Advanced UT in NDT combines cutting-edge techniques like Phased Array, Time of Flight Diffraction (TOFD), Total Focusing Method (TFM), Full Matrix Capture (FMC), Phase Coherent Imaging (PCI), Guided Wave UT (GWUT), and Corrosion Mapping to provide precise, real-time defect detection and material analysis. These methods ensure rapid, non-destructive inspections with high accuracy, essential for industries like aerospace, oil & gas, power generation, and more. We help safeguard critical assets by offering superior imaging, corrosion detection, and risk mitigation.

ADVANCED EDDY CURRENT TESTING

The advanced Eddy Current Testing (ECT) techniques, including PEC, PECA, CUI, and SPYNE, are cutting-edge methods designed to provide highly accurate and efficient inspection for a variety of materials and applications. PEC and PECA are powerful tools for inspecting complex structures and offering detailed imaging, especially in aerospace and power industries. CUI focuses on the challenging problem of detecting corrosion under insulation, while SPYNE offers an effective solution for inspecting large surface areas. These advanced methods are essential for detecting critical flaws and ensuring the integrity of components in industries that demand high precision and reliability.

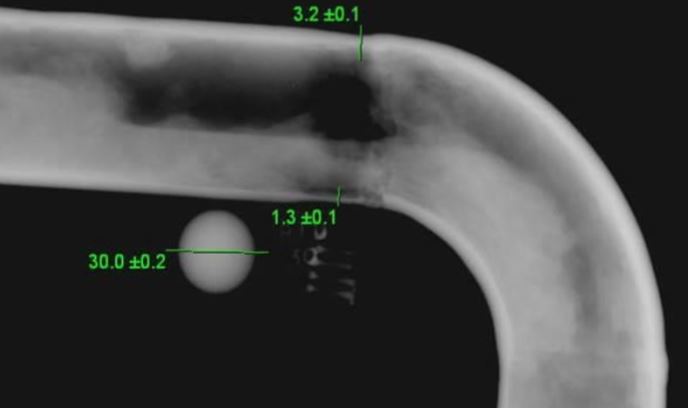

ADVANCED RADIOGRAPHY TESTING

Advanced Radiographic Testing (RT) leverages Computed Radiography (CR), Digital Radiography (DR), and Self-Contained Automated Radiography (SCAR) to deliver high-precision, non-destructive inspections, enabling faster, more accurate detection of internal defects and ensuring the safety and reliability of critical components across industries like aerospace, automotive, and manufacturing, such as Digital Radiography (DR) and Computed Radiography (CR), produce high-resolution images that highlight corrosion damage, allowing for more accurate analysis.